Decoction Mashing – Is it Worth the Effort?

02/23/2023

By Chris Pfeiffer

Do you love malt-forward, European lager styles? Do you enjoy exploring historical brewing methods and techniques? If so, then you have likely thought about decoction mashing. You may be wondering if it is worth the effort. Below, we’ll discuss the decoction mashing process and some things to consider when deciding if the method is right for you.

Historical Use

Brewers today have access to highly-modified malts with consistent quality. We also have “modern” tools like thermometers and temperature control technology. These tools are luxuries that were not available to most brewers hundreds of years ago. To the brewer of old, the decoction method was a necessary tool. Boiling the grain for extended durations breaks down the under-modified grain and allows the starches to be fully gelatinized. This unlocked the valuable starches captive within under-modified cellular walls of the grain and ensured more consistency in the mashing process. Since liquids boil at a consistent and constant temperature, it allowed the brewer to achieve consistent mash temperatures by taking much simpler volumetric measurements and without needing to actually measure mash temperatures.

Method

The process of conducting a decoction mash is actually quite simple and fortunately you likely already have the hardware that you will need. After initial dough-in, a portion of the mash is removed, then heated in a separate vessel, and then boiled (with constant stirring) and returned to the main mash to raise its temperature. I find a small 4-gallon pot is sufficient to hold and boil the decoctions. For measuring the amount of the decoction and transferring it to and from the mash, I use a 2qt stainless steel dipper, however, anything from a large soup ladle to a sauce pan to a Pyrex measuring cup could also be used.

In addition to the volume of the decoction, the brewer can adjust the number of decoctions used in the mash, the thickness of the decoctions and the boiling time to achieve their desired objectives.

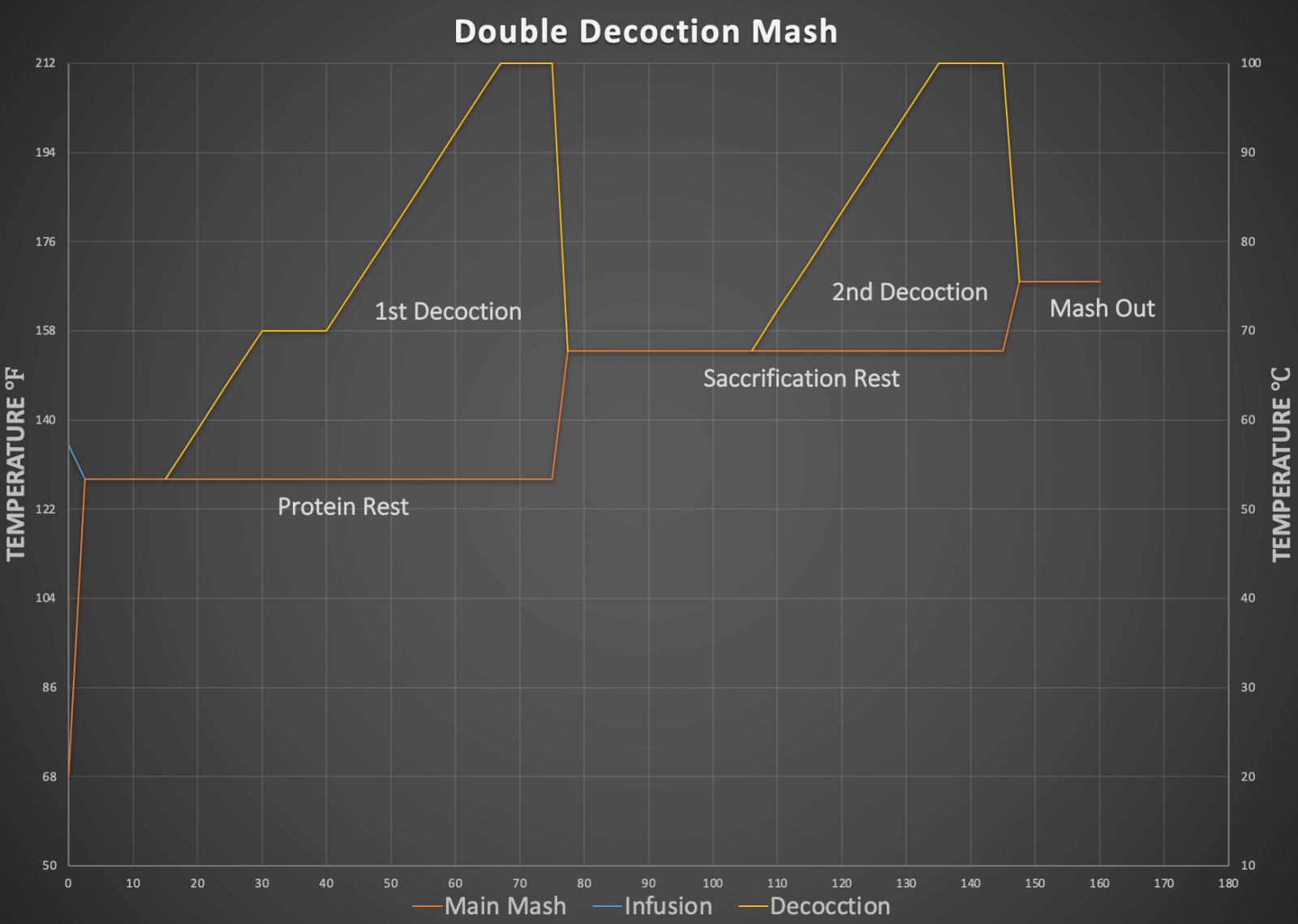

Decoction mash schedules are often expressed as time-temperature graphs like the one below which depicts a typical double decoction mash schedule.

Many variations of the decoction mash schedule exist as it has been used by brewers for hundreds of years.

Pros vs Cons

What does this mean to us as modern brewers? Clearly, the process is simple enough and it’s nice that it was functional for some brewers hundreds of years ago; but today we enjoy well-modified grain and accurate digital thermometers are very inexpensive - so why spend time and effort on this technique vs simpler methods such as infusion mashing? The short answer - melanoidins.

Unknown to early brewers, the decoction process also has some tasty benefits, namely, the formation of melanoidin compounds. Melanoidin compounds are formed at high temperatures via a process known as the Maillard reaction which occurs in the decoction mashing process when the thick mash is boiled. Melanoidin compounds are a family of chemicals that are responsible for the flavors we describe as cookie, biscuit, toasty, bready, and toffee and many of these flavors are highly desirable in many European styles such as Czech Pilsner or German Märzen. The decoction mashing technique can therefore be used to increase the desired malty-sweet flavor profile of the wort without the contribution of long chain sugars and unfermentable dextrins or style inappropriate cloying flavors that can result from the use of crystal malts.

In addition to increased melanoidin formation, decoction mashing has other benefits such as allowing the brewer to achieve better mash efficiency, higher and higher degrees of attenuation.

Exposing the grain to higher temperatures in the decoction process will guarantee complete gelatinization and liquefaction of the starch. The more starch that is “unlocked” from the grain the more starch that is available to be converted to sugars.

Likewise, the decoction method can also benefit those who are seeking to increase wort attenuation and produce a very fermentable wort. Like melanoidin content, high attenuation is also a desired characteristic of many European lager styles. The recent trends of hotter and dryer summers in European malt growing regions have led to malts with higher starch gelatinization temperatures. If the temperature required for starch gelatinization exceeds ~150F (outside the optimal range for beta amylase activity) then many starches will remain bound during the beta rest period and only accessible to alpha amylase. This leads to a less fermentable wort. Boiling portions of the thick wort and adding it back to the thin mash at beta temperatures can help solve this problem for the brewer.

While the decoction process comes with some benefits, we can’t escape the fact there are trade-offs. The process is significantly more time, labor and energy intensive compared to methods such as single infusion mashing. There are, however, some short-cuts the brewer can use to achieve some of the same benefits by other means.

Many brewers today enjoy choosing from a wide selection of malts when formulating their recipes. Brewers can use this diversity to their advantage. We can make some partial substitutions when formulating their recipe to increase the melanoidin content without performing a decoction mash. In fact, maltsters like Wyermann make a product called “Melanoidin Malt” for this very purpose. Here are some examples of some partial substitutions to consider:

• Cologne Malt in place of Pilsner Malt

• Munich Malt in place of Vienna Malt

• Melanoidin Malt in place of Munich Malt

In addition to recipe short-cuts, there are also some mash process short-cuts that can be used to achieve similar results as well. Above the critical temperature, starch gelatinization happens almost instantaneously and enzyme degradation is relatively slow. This means the brewer can alter infusion temperatures to achieve the desired result. For instance, the brewer can dough-in a thick mash at temperatures in the alpha amylase optimal range for a few short minutes and then quickly lower the mash temperature to the beta amylase optimal range with a second cold infusion. This technique allows better starch gelatinization while degrading beta amylase only minimally.

So, we can see that decoction mashing comes with some real benefits and can help a brewer gain added dimension to their beers, especially for European lager styles. Decoction mashing, however, is not the only means to consider. For me, it is a technique that I apply when time allows as I enjoy the traditional aspect of the method. My best Dunkels have been made with a decoction mash, however, I have made very good ones with infusion mashing as well.

What method is right for you? I would encourage you to give the decoction process a try and make the comparison yourself.

Cheers!

Related Products

All contents copyright 2024 by MoreFlavor Inc. All rights reserved. No part of this document or the related files may be reproduced or transmitted in any form, by any means (electronic, photocopying, recording, or otherwise) without the prior written permission of the publisher.