Download print friendly version

Download print friendly version

Congratulations on your purchase of a new MoreWine! Plate Filter. These filters are suitable for the clarification of both still and carbonated wines and beers. With proper care, maintenance and usage, this filtering unit should last you many happy and productive seasons. As with any MoreFlavor product, we welcome and encourage any and all customer feedback – both positive and negative. Let us know how your filter is working for you!

Section 1: Safety Information

Note: Before proceeding with the installation, operation or maintenance of this machine, please carefully review these instructions. At MoreFlavor!, it is of great importance to us that you are around to enjoy your finished product. Please observe all safety precautions completely.

1.1 General Safety Precautions

-

The failure to observe all safety precautions as laid out in this manual can result in a severe risk of injury or death. Please review all safety precautions thoroughly before using your filter.

-

Prior to starting the machine each time; check all structural parts, the motor, the pump head and all connecting hoses and pipes for mechanical cracks or signs of corrosion. Replace any damaged components prior to using the machine.

1.2 Filter Operation

-

This filter should not be used in conjunction with products not specified in this document.

-

This filter should not be used under environmental conditions other than those specified in this document. (Section 3.2)

-

Do not run the filter if any of the components appears to be missing or damaged – serious injury or death could result.

-

Avoid loose fitting clothing and keep long hair tied back while using this machine

-

Do not move the machine while in use.

CAUTION: This machine should not be used to filter any inflammable materials or in environments which contain inflammable materials due to the heat put out by the pump and motor.

1.3 Electrical System

Note: Before connecting to electrical power, make certain that the electrical system of your facility conforms with the specifications printed on the motor plate. If you are uncertain about this, consult a qualified electrician.

-

Do not operate the electric motor if the cover plates are missing, damaged or incorrectly mounted.

-

Should the motor fail to start or begin to overheat, disconnect it from the power source immediately.

1.4 Cleaning and Maintenance

Note: Before carrying out any cleaning or maintenance operation, ensure that the machine is switched off and disconnected from electrical power, that all parts have cooled from usage and that all pressure has been relieved from the system.

-

Check that all switches and electrical connections are in good repair.

-

After long periods of storage, before the first use of the season, ensure that all screws which connect the various parts of the machine are correctly tightened.

-

Do Not alter the structural components of the machine in any way.

-

After each maintenance check, be sure that the machine is correctly assembled, paying particular attention to the pump and motor housings.

-

Before starting the machine again, be certain that all tools used during repair or maintenance have been removed.

-

Be sure to wash the unit with non-toxic, food grade materials only.

1.5 Waste Disposal

MoreWine! would like to remind you that waste disposal regulations vary from district to district and are subject to local and Federal regulation. As always, we encourage you to dispose of your waste products in a safe and socially responsible manner.

Section 2: Description of Machine

2.1 Parts and Nomenclature

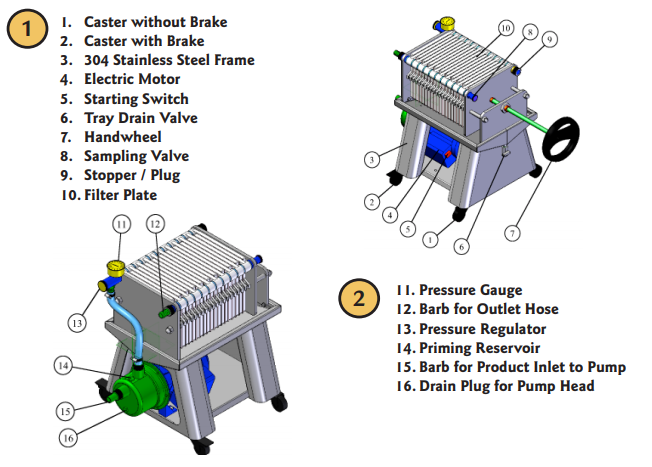

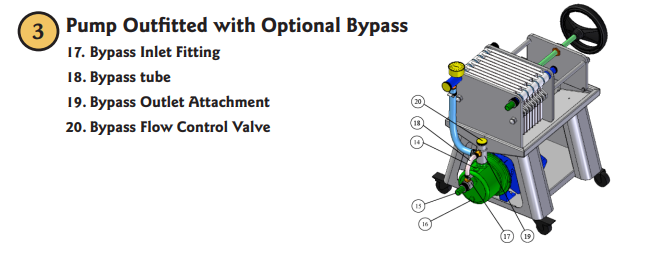

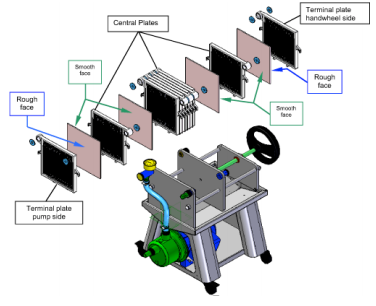

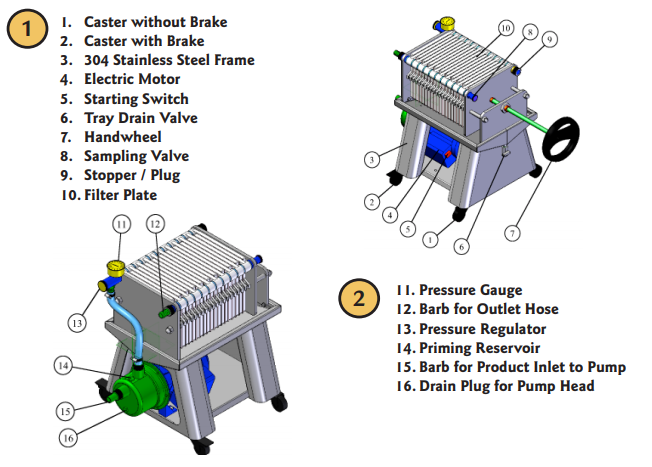

The machine can be divided into three functional parts or sections:

-

Stainless steel frame with casters, two of which lock

-

Filtration unit with food grade filter plates

-

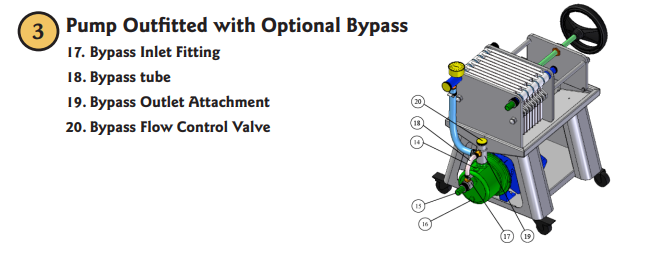

Assisted priming electric drive pump which can be equipped with a bypass for more consistent product delivery.

Section 3: Specifications & Indications

3.1 Technical Specifications

|

Model |

10 Plate |

20 Plate |

40 Plate |

|

Hourly Production (gal/hr, approx.) |

79 |

158 |

316 |

|

Number of Filter Plates |

11 |

21 |

41 |

|

Number of Filter Sheets |

10 |

20 |

40 |

|

Filtering Surface Area (m²) |

0.4 |

0.8 |

1.6 |

|

Motor Output (HP) |

0.5 |

0.5 |

0.75 |

|

Voltage Supply (V) |

110 |

110 |

110 |

|

Frequency (Hz) |

50 |

50 |

50 |

3.2 Proper Running and Storage Conditions

-

The machine is designed for indoor use and should be no means be used in or exposed to the rain. Indoors, it should be positioned as far as possible from any running or splashing water. If the electric pump becomes wet, discontinue use and disconnect from the power supply until all electrical components of the machine have dried.

-

The machine’s components have been designed to function between 50 and 104°F (10 – 40° C). 5° variations in temperature will be fine if they are for short periods. The machine should be stored between 23 and 140°F (-5 – 60° C)

-

The temperature of the product being filtered should always be between 23 and 140°F (-5 – 60° C)

Section 4: Using the Filter

4.1 Choosing a Filter Sheet

|

Part # |

Micron Rating |

Max Pressure During Use (psi) |

Filtering Capacity (gal/hr/sheet) |

Application |

|

FIL919 |

9-10 |

45 (3.0 bar) |

15 (20x20cm)

50(40x40cm)

|

Rough filtration of white musts pre-fermentation |

|

FIL920 |

5-7 |

45 (3.0 bar) |

15 (20x20cm)

50(40x40cm)

|

Initial polish of all wine or beer types. |

|

FIL921 |

2-3 |

45 (3.0 bar) |

9 (20x20cm)

35 (40x40cm)

|

Polishing – clear wine or beer filtration. |

|

FIL923 |

0.8 |

21 (1.5 bar) |

5 (20x20cm)

20 (40x40cm)

|

Sterile filtration for removal of yeast. |

|

FIL924 |

0.45 |

21 (1.5 bar) |

5 (20x20cm)

20 (40x40cm)

|

Sterile filtration for removal of bacteria – will remove some flavor & color from the beverage. |

4.2 Insertion of Filter Sheets

-

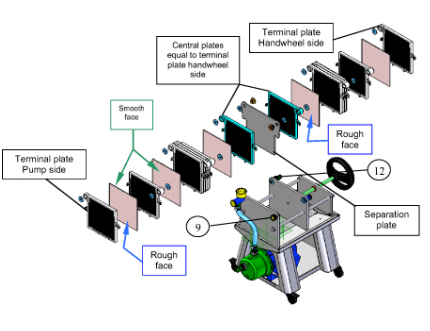

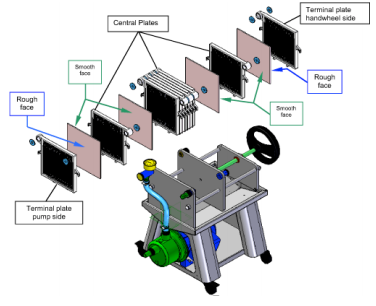

Filter Sheets should be inserted with one sheet between each set of plates. The sheets have a rough and a smooth side. The “smooth” side appears to have a very fine crosshatch pattern to it while the “rough” side appears similar to frothy milk. The sheets need to be inserted into the machine in a rough-smooth-smooth-rough pattern, starting with a rough side facing the end plate at the pump side.

-

Each of the plates has a barb which accepts an included 4 mm rubber gasket to seal the system. There are two thinner, 2 mm gaskets included as well. These gaskets are inserted between the terminal filter plates and the steel endplates which are part of the frame of the filter, at the Pressure Regulator (13, Sec 2.1) and the handwheel-side plug (9). Once everything is in place, tighten the handscrew so that there is sufficient pressure to seal the system while it is running – this will need to be pretty tight.

*Note: Do not leave any spaces between the plates empty. If you run short of pads, remove the appropriate number of plates so that the filtering set up runs sheet-plate-sheet-plate all the way through. Failure to “fill” the filter with sheets will result in leakage during use.

4.3 Use of a Double Filtration Plate

-

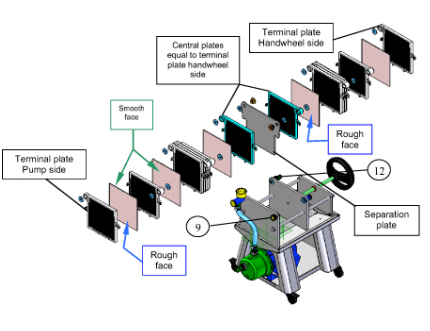

MoreWine!’s plate filters can be outfitted with a Double Filtration Plate (WE915 / WE916) which allows you to create two “chambers” where filter pads of different micron ratings can be used in serial to one another.

-

Note that due to the need for the extra end plates on either side of the separation plate, it may not be possible to fit as many pads into the filter.

-

Also note how the position of the Plug / Stopper (9, see 2.1) and the Barb for the Outlet Tube (12) have changed position to accommodate the double filtration

-

DO NOT use pads with different micron ratings in the same “chamber” during double filtration.

4.4 Connecting and Running the Filter

It may be helpful to you to refer to the diagrams in section 2.1 (p.X) while reading this part of the instructions. The different parts of the machine will be referred to with the same numbers that they are listed as earlier in this paper. It is important to double check that all connections are tight and there are no leaks prior to running your actual product through the filter. Circulating a sanitizing agent is a great way to do this. We recommend the use of SaniClean (

CL27) for this procedure. Note that a small amount of seepage is normal during the filtering process, as this is part of how the system stays sealed. Seepage will collect in the drainage tray underneath the filter plates.

-

To connect the filter, attach your hose from the vessel containing the product to be filtered to the Product Inlet (15), and connect a tube leading from the Product Outlet (12) to whatever vessel you wish the filtered product to wind up in.

-

Remove the cap to the Priming Reservoir (14) and fill. Replace and re-tighten the cap.

-

Close the Pressure Regulator (13) about half way.

-

Turn on the motor.

-

Open the Sampling Valve (8) and allow the air to be evacuated from the filter. Close the valve only once there is no more air being discharged.

-

By adjusting the Pressure Regulator (13), set the pressure to about 4 psi (0.3 bar), maintain this pressure for 10–15 sec. Now adjust the regulator until it reads the correct operating pressure for the filter pads you are using

-

During operation, periodically check to ensure that the Pressure Gauge (11) is still reading correctly and consistently. Small adjustments may be necessary and are normal.

If the product is not dispersed within a few moments of switching on the pump, double check to make sure that the Inlet Tube is correctly connected and that no air had made its way into the system.

-

When you’re finished filtering, or if the pads become clogged, turn off the pump motor and unplug the machine. Wait at least 3 minutes before loosening the handwheel to ensure that all pressure has dissipated out of the system. Using the Drain Valve (6), empty the collection tray.

4.5 Filtering Carbonated Products

One of the attractive features of a plate filtering system is that it is possible to filter carbonated products such as bright beer or sparkling wine. The essential part of this is that the receiving tank needs to be pressurized so that you do not lose too much of the carbonation of the beverage in the process. You will always lose a little bit of the carbonation, but it can be minimized. Here’s an example which lays out the principles – it’s pretty easy to do:

Let’s say that your beverage is already carbonated to 15 psi, just pressurize the receiving tank to 10–12psi and make sure that you run the filter at 1 bar (14 psi) or higher. Because the filter assembly seals by positive pressure, your beverage has no lower-pressure place to let its bubbles out into. By keeping the receiving tank at a slightly lower pressure than the delivery tank, you encourage any carbonation which is scrubbed out of the liquid on its way through the filter pad to travel down the pressure gradient and dissolve back into the product. This also encourages good product flow through the system. Once all of the beverage is in the receiving tank, turn the pressure up to whatever level of carbonation you desire in it. It is important to use reinforced tubing for the outlet when filtering a carbonated product.

4.6 Regular Maintenance

Before carrying out any maintenance or repair operation, be sure the machine has been turned off, allowed to cool and is disconnected from electrical power. Failure to observe these measures could result in serious injury or death.

-

The filter unit should be cleaned thoroughly after each use to remove any deposits from the product being filtered. MoreWine! recommends the use of hot water and PBW (CL25) for this procedure. Be sure to rinse thoroughly after the administration of a cleaning product. MoreWine! reminds you that observance of strict cleaning protocols in the brewery / winery is the most effective tool in preventing the infection of future batches.

-

It is possible to steam sterilize the system after rinsing it only if you are using NORYL plates. Standard MOPLEN plates cannot be steam sterilized.

Section 5: Troubleshooting

|

Issue |

Cause |

Remedy |

|

The pump does not draw. |

Air has entered the system

The impeller pump is clogged

|

Ensure that the Inlet tube is intact and submerged. Re-fill the Priming Reservoir and re-start system

Disassemble and clean pump head

|

|

The circuit is not pressurized |

See above |

See above |

|

Excessive seepage during

operation

|

The entire unit is not sealed adequately

The filter sheets are not suitable for the product, or the seals are worn

|

Using the handscrew, seal the filtering pack more tightly

Replace the filter pads or seals as necessary

|

|

The filter does not reach the expected pressure |

Incorrect filter pads being used or incorrect product being filtered |

Replace filter pads. Be sure that unit is used only as specified in this document |

|

The filter exceeds the desired pressure |

Use of incorrect filter pads |

See 4.1 for filter pad selection |

Section 6: Warranty

This plate filter comes standard with a 1 year MoreWine! warranty, effective from the date of purchase. This warranty covers any manufacturer defects or damage incurred in the delivery of the machine. This warranty DOES NOT cover.

-

Damage caused by incorrect installation or maintenance,

-

Damage caused by inadequate or incorrect electrical or pneumatic supply

-

Damage caused as a result of failing to observe the precautions laid out in this manual

-

Damage caused by modification of the machine

MoreWine! reserves the right to repair or replace any parts of the unit deemed to be defective at their discretion. We will always work with you to keep you up and running.

MoreWine! takes no responsibility, explicit or implied, for any damage to premises, lack of production, personal injury or death that arise from the use of this plate filter.

Download print friendly version

Download print friendly version