A Look At Brewing Beer In A Bag (BIAB)

08/02/2017

By Vito Delucchi with Contribution from Adam Wyss

.jpg)

Brew in a Bag Made Simple

Equipment:

Brewing Instructions:

-

All liquor needed for the brew is added to the kettle and heated to strike temperature.

-

Adjust pH of Water (Recommended but not required)

-

At strike temperature, a bag is added to the kettle and the entire grain bill is added to start the mash.

-

The mash temperatures are maintained by occasional heat applications and stirring for usually 90 minutes.

-

The bag which holds the mash is removed at the end of the mash period.

-

Follow same boil process as extract/all grain.

“It’s My Brew In A Bag Baby” - A Look At Brewing In A Bag (BIAB)

Brew in a Bag (BIAB) is an all grain brewing method that can be done using a single vessel. BIABs rise in popularity and refining of the process is attributed to an Australian home brewing forum. My first shot at brewing in a bag was in 2011. At the time I had been brewing extract for a few years and was looking to make my way into all grain brewing. My motivation for trying BIAB was mainly financial and also it seemed simpler than a traditional all grain setup. I already owned a kettle and basically only needed to purchase a good sized bag. This low cost of entry into all grain brewing was definitely appealing to me. I ended up brewing two or three batches using the BIAB method before picking up a MT (Mash Tun) and HLT (Hot Liquor Tank). From what I recall those batches turned out well overall, but looking at my records, they suffered from low efficiency. However, the recent batch I brewed had normal expected efficiency. But I am getting ahead of myself, more on that later.

The BIAB Equipment

The most noteworthy part of BIAB is the minimal amount of equipment needed. All you need is a Kettle, Large Bag, Heat Source and something to stir with. Your kettle needs to be big enough to handle the full volume of liquor (hot water) and grain. Assuming you want to brew 5 gallon batches, I would recommend using a 10 gallon kettle. That size will allow you to brew beers up to 1.070 original gravity. The bag will need to be large and strong enough to hold the amount of wet grain you will be using. The Bag I used was our MoreBeer! Mesh Bag with Drawstring - 29 in. x 29 in. (Item #:

BAG26). It is large enough to hold up to 35lbs of grain and is very durable.

The BIAB Process

Step 1. The overall process is fairly simple due to less moving parts (equipment). First thing you will need to figure out is how much hot liquor (water) you will need. To calculate this you will need to know the following variables: grain bill, grain absorption, desired finished batch size, boil off rate and trub loss of your kettle.

There are plenty of online calculators, spreadsheets and software with built in profiles to assist in this calculation. For my batch I was using 10.5 pounds of grain. I figured on 0.12 gallons of absorption per pound of grain. I was aiming to have a finished batch size of 5.5 gallons. The extra 0.5 gallons was to account for loss in the fermenter. The boil off rate and trub loss of the 15 gallon kettle I was using I calculated at 1.25 gallons per hour and a 0.25 gallon of trub loss. Working through these numbers my 10.5 pounds of grain was going to absorb 1.26 gallons of water (Note absorption rates vary based on the crush of your grain). The calculation is Grain bill x Grain Absorption (10.5 x .12). Then you just add up the other variables to find out how much liquor (water) you will need.

“Grain Absorption” 1.26 gal + “Finished Batch Size” 5.5 gal + “boil off rate” 1.25 gal (60 min boil) + “trub loss” 0.25 gal = 8.5 gallons hot liquor

Step 2. One thing I did differently from my previous BIAB batches was as to adjust the pH of my water using lactic acid. The water I was using had a pH reading in the high 7’s. To get the greatest extract yield from your grain you want your pH in the 5.2-5.6 range. But that is a whole other article...

.jpg)

Step 3. Once we have our hot liquor volume needed, the rest of the process becomes much easier. The next step is to warm the hot liquor to the temperature needed in order to hit the desired mash temp. I was shooting for a 150F mash so I heated the 8.5 gal to 156F. Since we are adding the total volume of hot liquor it will be a very thin mash. This will make the temperature delta between the grain and desired mash temp a lot closer. I would expect 4-6 degrees fahrenheit loss based on experience and what I have read. I would rather turn my burner on for a second and heat my mash then add cold water to cool it and mess with my volume/efficiency calculations.

With our strike water now heated to156F, it’s time to turn off the flame. Next attach the mesh bag to the kettle and quickly but carefully add your grain. Once your grain has been added to the water give it a good stir to make sure there are no dough balls. Many sources suggest a 90 min mash when doing BIAB. My previous BIAB batches were 60 min mashes. The longer mash time will also help with efficiency.

Step 4. During the 90 minute mash, I checked the temperature every 30 minutes via the thermometer on the kettle and another glass thermometer in the mash itself. Each time I checked the temp it had dropped 4-6 degrees from my desired 150F mark. To heat it back up I simply turned the burner on the lowest setting possible and stirred the mash. I would also recommend lifting the bag off the bottom of the kettle while heating. Especially if your kettle does not have a thick tri-clad bottom.

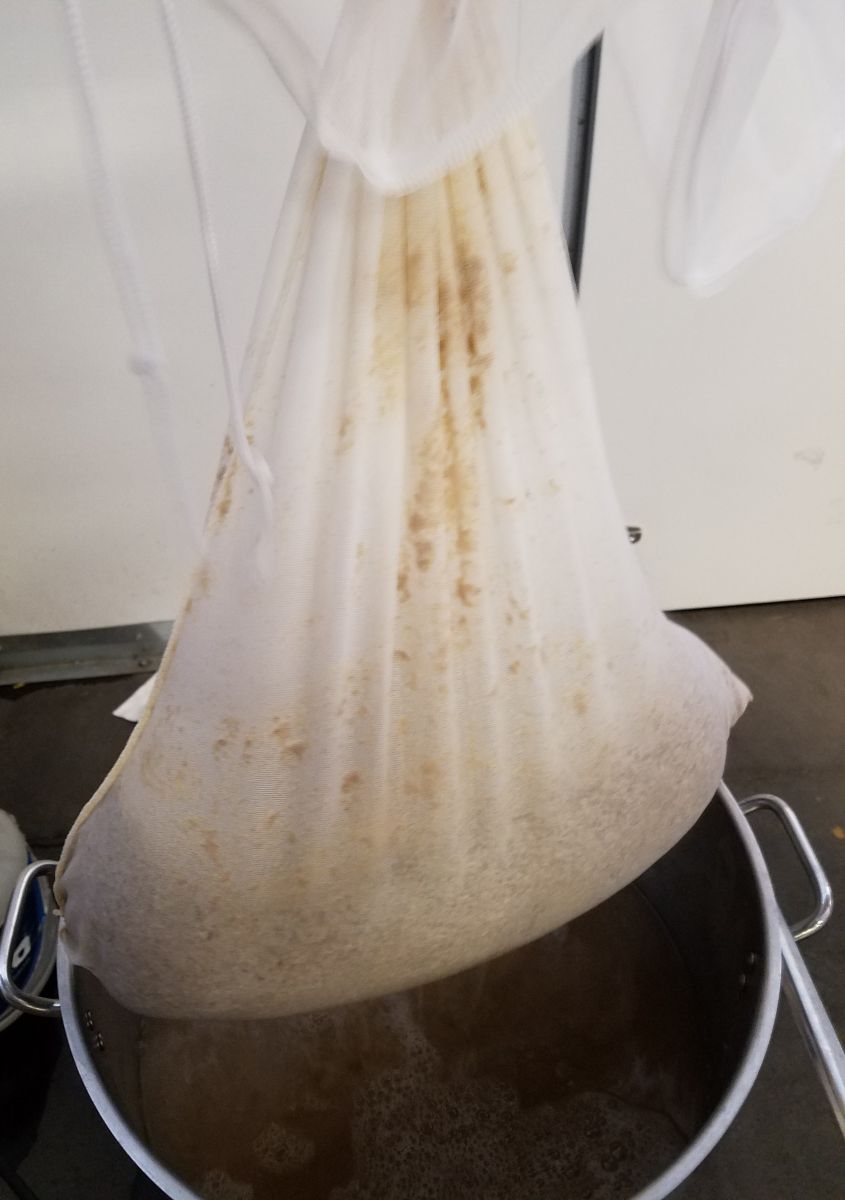

Step 5. Once you have hit the 90 minute mark, it’s time to remove the bag of spent grain. Be sure to use thick rubber gloves as the grain and runnings are extremely hot. You also want to make sure you get as much of that sweet wort out of the bag as you can. I just held the bag over the kettle for about 2-3 minutes, allowing it to drain. I have seen pulley systems used or you can simply set the bag on the mash paddle over the kettle etc.

Step 6. From this point on, the process is exactly the same as brewing an extract batch. Heat your wort up to a rolling boil, add your hop additions, clarifiers and then cool to pitching temp & add yeast

The Conclusion

I was expecting the brew day to be shorter due to having less equipment to clean and steps overall. However it turned out to be about the same as a normal all-grain brew (4-5 hours). Yes you have less equipment to clean, but generally you are doing that cleaning during the boil on an all grain batch. So you are not necessarily saving time, just less work overall. One of the biggest benefits of BIAB is that it requires less equipment, that can be costly and take up more space. Another positive is you will also never experience a stuck mash, due to the fact you can simply lift your mash right out of the kettle. One thing I thought might contribute to less efficiency and possibly lead to cloudier wort was no vorlauf (recirculating) step. Visually I did not notice any difference of the finished wort from what I would expect. I also think the adjusted pH and longer mash mitigated the need to thoroughly rinse the grain.

All in all it was a great brew day that produced excellent wort. I was also very happy with the efficiency, I got at 79% (your milage may vary). I would highly recommend BIAB to anyone looking to step into All grain brewing from extract. Especially prior to investing in a complete multi vessel AG system. Or possibly for those looking to downsize their brewing setup due to space constraints.

Pros

-

Less equipment – less space

-

Lower cost – no MT/HLT

-

Less equipment to clean on brew day

-

No risk of stuck mashes

-

Less fuel/energy used

Cons

-

Many myths and misconceptions

-

Less information/focus for BIAB

-

Fewer reasons to buy fancy new toys (brewing equipment)

Lessons Learned: Process

-

Stir often and adjust temp if needed

-

I get higher efficiency if I increase the mash duration to 90 minutes and by adjusting the pH

-

Hang the bag over the pot to drain, or put it in a bucket and dump the drained wort in the kettle later.

-

Use online tools to help calculate strike temp and volume.

Lessons Learned: Equipment

-

Don’t simply trust the temperature gauge on the side of your kettle when the bag is in the kettle.

-

Use a another thermometer in the mash to take measurements.

-

A false bottom can provide a buffer to further reduce burning the bag or grain.

-

Also provides bag failure mitigation.

Related Products

All contents copyright 2024 by MoreFlavor Inc. All rights reserved. No part of this document or the related files may be reproduced or transmitted in any form, by any means (electronic, photocopying, recording, or otherwise) without the prior written permission of the publisher.

.jpg)

.jpg)

.jpg)